![]()

With their business expanding, Allard Emballages decided it was the opportune moment to implement a planning and MES software to replace their internal customised system. Their older system worked well for them for many years, however, as with many internal systems, they started to experience the downfalls lacking support while the business complexity is changing. With objectives to reduce the risk of technology obsolescence and increase efficiencies, Allard Emballages decided the best solution for their requirements was to implement the Greycon software into their Varennes site.

![]()

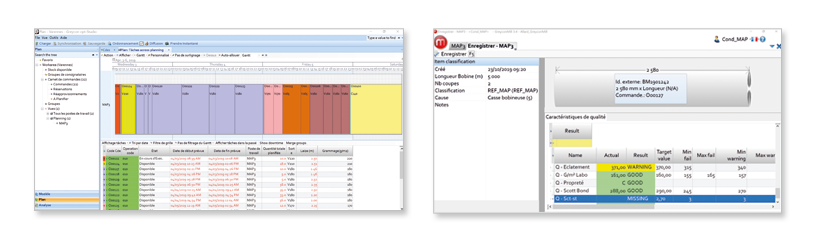

Working closely with Allard Emballages, considering their requirements and necessities, Greycon implemented opt-Studio for order entry, planning and scheduling, and GreyconMill for manufacturing execution. The software included production recording and tracking, quality management, transport planning and shipping, product labelling and reporting with GreyconMill capability to integrate with Microsoft Reporting Services.

The project was a great success with a smooth transition from the older in-house MES system to the new one, allowing the Varennes team to continue with their normal operations without issues.

![]()

-

Visibility of order flow and status

-

Integrated system (covering planning, production, quality, logistics)

-

Up-to-date technology & long-term support

Greycon Newsletter

Sign-up for the Greycon Newsletter and be the first to receive the latest updates, news and releases